Whether on land, in the air or on the water, the areas of application for our NEVEON products cover every passenger transport variation. NEVEON develops solutions that extend from the initial concept phase to the series product and offers simple blanks, as well as complex system solutions. As a responsible supplier, we understand partnership as meaning customer satisfaction.

.automotive

FAST, FIT AND FUNCTIONAL FOR THE AUTOMOTIVE INDUSTRY

NEVEON manufactures foams with different densities and properties for optimum use in cars. We offer functional foam parts for interior applications and are a professional and reliable partner with our crom series.

Foam products used:

foam.light material.composite

.aviation

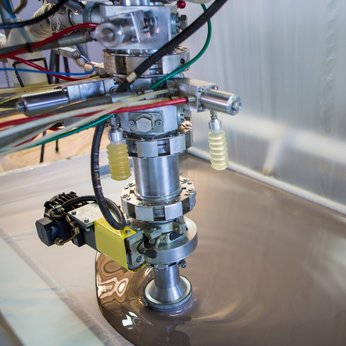

INTELLIGENT COMFORT READY FOR TAKE-OFF

As a manufacturer of aircraft seat cushions and covers, we supply the world's major airlines with innovative and sustainable aira products. From the initial design to prototyping, fire tests and series production, we offer everything on a one-stop store basis with regard to both original items and spare parts.

Foam products used:

foam.comfort foam.sensitive

.railway

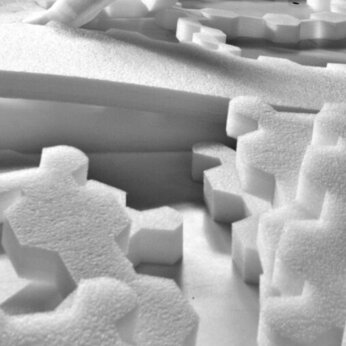

RIGHT ON TRACK WITH THE LATEST REQUIREMENTS

Our tailor-made railway seat cushions and seat covers ensure optimum passenger comfort and naturally meet the strict, international requirements of the rail industry with regard to safety and fire protection. Irrespective of whether seat configurations or special customer demands for acoustics or sound insulation are involved, our experienced NEVEON team will find the ideal solution for every requirement.

Foam products used:

foam.protect foam.sensitive