As an integrated foam company with many years of experience, we are the one-stop shop for all foam needs. From producing standard and specialty foams in over 300 grades to further processing and refinement into semi-finished and finished products for a wide range of industries and retailers – we offer tailor-made solutions for a wide range of needs. Our scalable processes enable us to support all projects as a competent partner from the prototype phase through to large-scale production.

Polyurethane foams: The invisible heroes of our everyday lives

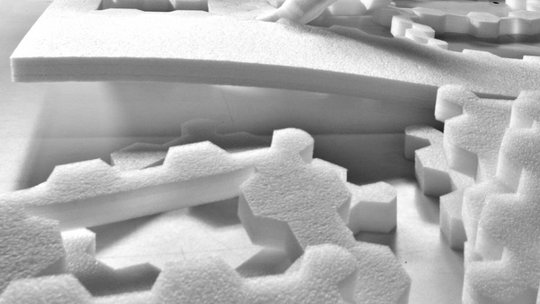

Cozy mattresses, comfortable sofas, ultra-light aircraft seats, energy-saving insulation, effective noise and sound protection, protective packaging, precise filters and seals, or reliable sports equipment: Polyurethane foams are the heroes of our everyday lives. They improve the energy balance in many contexts and make our lives more comfortable and safer – quite simply, better!

Watch our video to find out how we produce our foams! Video element