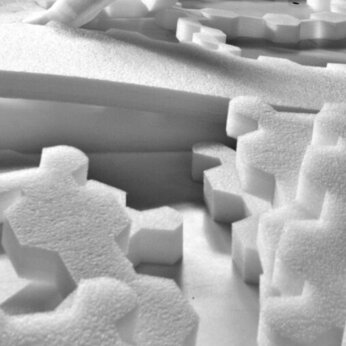

NEVEON foam.light foams have been specially developed for the thermoforming process and are available in the form of precisely cut sheets. Thanks to their low density and high compression hardness, our foams are particularly suitable for use in self-supporting components. Despite their low density, our foams have exceptionally good acoustic and thermal properties and are therefore particularly suitable for use in the engine compartment or on gearboxes in the immediate vicinity of the heat source.