At NEVEON, we are convinced that innovation is the key to a better life. That’s why we are rethinking foams – with technological excellence, creative solutions, and the courage to push boundaries. For better products. For sustainable success. For our customers.

In our international R&D hub, with locations in Zgierz (Poland) and Linz (Austria), we bring together all our expertise. Here, experts from a wide range of fields work together on innovative, practical solutions that will sustainably transform the industry.

Our R&D Hub at a glance

PU Innovation Pilot Plant – Zgierz, Poland

Practical material development and raw material testing

The heart of our R&D hub is our development and testing facility. Here, we quickly and efficiently test new PU foams and raw materials before transferring them to one of our seven foam production lines.

- Production of test foams with volumes of 1 to 3 m³ – perfect for flexible, cost-effective, and resource-saving development

- Testing and validation of new raw materials

- Very high throughput with minimal material usage

- Ideal for testing customer-specific foams or high-risk ideas under real-world conditions

“In our PU pilot plant, we test new foams and raw materials on a small to medium scale under realistic production conditions – saving time, costs, and resources.” Maciej Ratajczyk, our Team Leader Advanced Materials

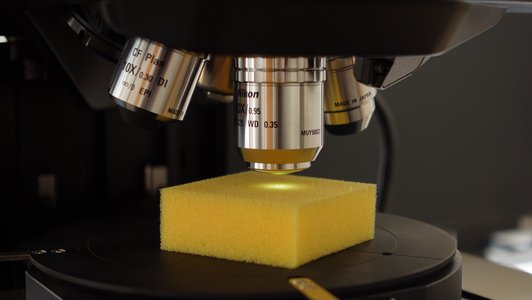

PU Analytics Lab – Zgierz, Poland

Precision meets foresight

In our expanded analytics lab, we combine chemical quality testing with research and development under one roof. This enables us to ensure the highest product quality, for example by carrying out tests for volatile or migrating organic compounds directly in-house.

- In-house emissions testing – for maximum safety in sensitive applications such as mattresses or vehicle interiors

- Control and evaluation of raw materials used

- Monitoring of supply chains – from raw material to finished product

- Development of innovative analysis methods for new and recycled raw materials

“With our expanded analytics lab, we now have even greater control over the quality of the raw materials used and the products manufactured from them.” Michał Włodarczyk, Chemik Analityk at NEVEON

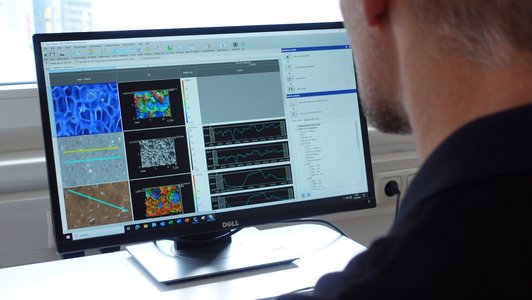

Data Science & Simulation – Linz, Austria

Driving innovation through digitalization

Using state-of-the-art simulation methods and data-based analysis, we test material behavior, calculate the product carbon footprint, and optimize processes and technical solutions. Already during the design phase, we precisely and proactively evaluate product performance – for example, in heating system insulation. This results in more efficient, more sustainable systems with maximum performance.

- Maximum transparency across the entire production process

- Certified and validated product carbon footprint calculation

- Development of material models to specifically enhance performance

“Data science provides us with valuable insights for better, more sustainable products. Simulations reveal optimization potential early – even before production begins.” Christoph Gruber, Team Leader Data Science

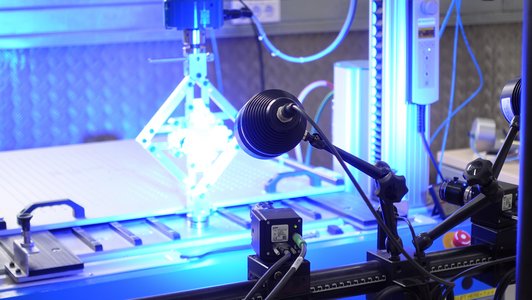

Prototyping and Testing – Linz, Austria

Proving reliability

In our testing center, we put our developments through their paces – from mechanical properties to long-term performance. Only what passes here moves on to the next stage. In prototyping, we trial new manufacturing processes and assess early on whether they reliably achieve the desired product properties.

- Testing of new manufacturing processes

- Integration of new functionalities into products for customer presentations – e.g. sensor technology in aircraft seats

“Through precise testing procedures, we optimize resource use, detect weak points early, and improve new designs in a targeted way during prototyping.” Alexander Maier, our Head of Physical and Mechanical Testing